- Joined

- Mar 6, 2004

- Messages

- 13,314

- Reaction score

- 123

- Location

- Plantersville

- First Name

- Rebecca

- Last Name

- Reed

First, this is the reason my horn wasn't making horn noises when pressing the horn button. Go figure. At least Ana (anaconda) has small enough hands to get in there and re-clip it into place.

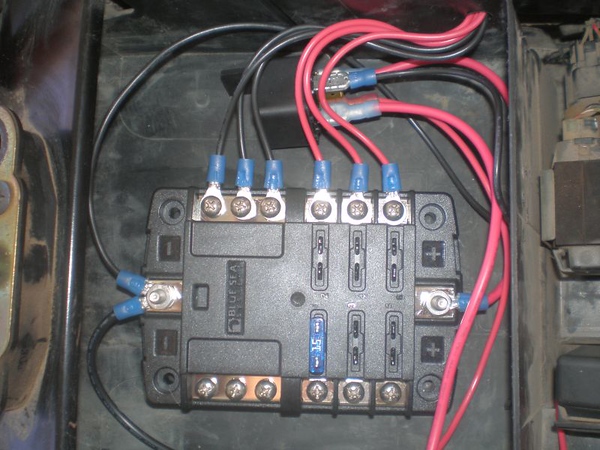

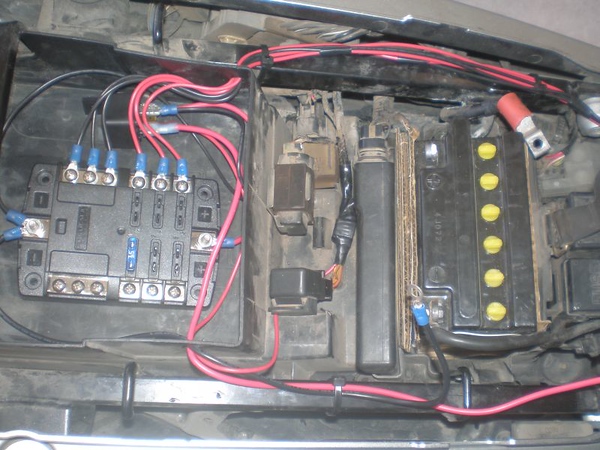

I positioned the fuse block in the lower section of my under-seat pan with space all around for the connectors. In this pic, you can see my "old" wiring system - an in-line fuse hooked directly to the battery, attached with zip ties to the front of the pan. I had an SAE acessory plug (trailer hitch plug) on the end of it so I could adapt miscellaneous things to it (battery tender, GPS, Chatterbox).

I used a connector clip to tap into the thick orange wire here, which we confirmed is switched. We used this for the relay to keep the entire block switched. Yes, I would inevitably kill the battery leaving things on without it.

Wire placement starting. I ran all three sets of lines up to the front of the bike, using one for heated grips with a switch and two for accessory SAE plugs (GPS and XM/Chatterbox). Most people hardwire their accessories, but I like the plugs because they're sturdy and allow me to remove all the gadgets and mountings for track days and major maintenance.

Power, ground (direct to battery) and relay lines were brought into the pan from one side and the individual fused lines left the box from the opposit side.

A close-up of the tap for the relay. This was kept in the space between the battery and the pan, with the relay itself mounted inside the pan with the block.

Other than the tap, all of the connections were soldered and heat-shrink tubing encased it all.

Next up was heated grips. I followed Ana's lead and wrapped the Symtec heating elements around the grips, then covered them with the extra pair of Grip Puppies she had.

I located the small rocker switch for the grips right below the bars on the left fairing trim. I bet you can imagine how many sets of eyes were on me as the drill was placed in my hands and I began to make a hole in my bike.

I think there's more zip ties on my bike now than most race bikes

These folks were there to watch/help/ridicule during the process, as well as work on wiring things on/to/with their own bikes.

This guy likes to make fun of me for anything and everything, but he does it because he cares. Well, at least that's what they keep telling me.

Woohoo! We're done!

I positioned the fuse block in the lower section of my under-seat pan with space all around for the connectors. In this pic, you can see my "old" wiring system - an in-line fuse hooked directly to the battery, attached with zip ties to the front of the pan. I had an SAE acessory plug (trailer hitch plug) on the end of it so I could adapt miscellaneous things to it (battery tender, GPS, Chatterbox).

I used a connector clip to tap into the thick orange wire here, which we confirmed is switched. We used this for the relay to keep the entire block switched. Yes, I would inevitably kill the battery leaving things on without it.

Wire placement starting. I ran all three sets of lines up to the front of the bike, using one for heated grips with a switch and two for accessory SAE plugs (GPS and XM/Chatterbox). Most people hardwire their accessories, but I like the plugs because they're sturdy and allow me to remove all the gadgets and mountings for track days and major maintenance.

Power, ground (direct to battery) and relay lines were brought into the pan from one side and the individual fused lines left the box from the opposit side.

A close-up of the tap for the relay. This was kept in the space between the battery and the pan, with the relay itself mounted inside the pan with the block.

Other than the tap, all of the connections were soldered and heat-shrink tubing encased it all.

Next up was heated grips. I followed Ana's lead and wrapped the Symtec heating elements around the grips, then covered them with the extra pair of Grip Puppies she had.

I located the small rocker switch for the grips right below the bars on the left fairing trim. I bet you can imagine how many sets of eyes were on me as the drill was placed in my hands and I began to make a hole in my bike.

I think there's more zip ties on my bike now than most race bikes

These folks were there to watch/help/ridicule during the process, as well as work on wiring things on/to/with their own bikes.

This guy likes to make fun of me for anything and everything, but he does it because he cares. Well, at least that's what they keep telling me.

Woohoo! We're done!

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to