PhilS

0

Well Guys:

Since it's 20 degrees, snowing, and icing here, I thought I take the bike apart!

A while ago Scott MetrikMetal mentioned that he had taken the left side generator cover off to polish it and noticed this his internal wiring harness had started to wear through. His bike was running perfect, but, continued wearing would have left him stranded probably in the middle of the desert, or ocean, or something as these hidden things usually do. So, he fixed it and life went on. Wondering if this is a systemic issue or not, and the fact that I was bored and needed "Bandit Therapy", I ventured in.

Here is the write up.

I ordered 1 cover gasket 11483-18H00 for $8 and 2 upper bolt gaskets 0916806023 for about a buck each or so and a tube of 1207 bond (I used Honda Bond. It's a semi-hardening sealer).

Here's a shot of everything you need to get started. And yes, Red Bull was needed.

Step one - pull off the primary drive cover.

Step two - pull off the body work, if in fact you have some.

Step three - take out the 10 generator 8mm bolts.

Step four - notice, the top two bolts have a gasket washer on them.

Step five - pull the cover off straight and in-line. It is tough to pull as there is a big magnet holding things in place in the generator. There are two dowel pins lining it up too. Just pull slowly with both hands and watch getting pinched as it slams back shut!!! A bit of oil comes out too - just be prepared.

A bit of oil comes out too - just be prepared.

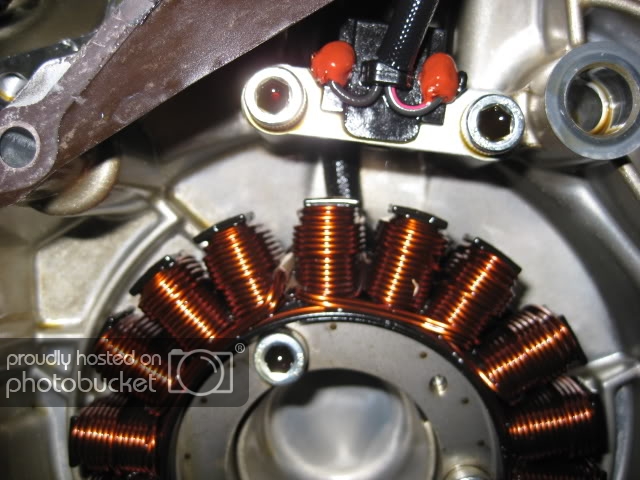

Step six - look inside for any damage. In mine, there was none.

Step seven - scrape off ALL old gasket materials.

Step eight - use your 1207 sealer (Honda Bond or Suzuki Bond) and lightly hit the left and right sides with a little where the case halves come together.

Step nine - ensure both dowel pins are in, then install your new gasket.

Step ten - SLOWLY with both hands and STRAIGHT IN, reinstall the cover onto the dowel pins. WATCH PINCHING YOUR FINGERS!! Use a rubber tap hammer to SLOWLY tap it back in place. When ready and it is aligned, insert the top two bolts. I used new gasket washers only because they were cheap and I like new stuff. Reinstall the balance of the bolts and tighten. The manual did not seem to give a torque setting, so I just tightened.

Step eleven - reinstall the primary drive cover, wipe everything off, and fire it up to do a leak check. In my case, all was fine!!

Step twelve - reinstall the body work if in fact you have some, polish it up again, and be thankful it all works again!!! After this twelfth step, consider you and your bike healed.

Since it's 20 degrees, snowing, and icing here, I thought I take the bike apart!

A while ago Scott MetrikMetal mentioned that he had taken the left side generator cover off to polish it and noticed this his internal wiring harness had started to wear through. His bike was running perfect, but, continued wearing would have left him stranded probably in the middle of the desert, or ocean, or something as these hidden things usually do. So, he fixed it and life went on. Wondering if this is a systemic issue or not, and the fact that I was bored and needed "Bandit Therapy", I ventured in.

Here is the write up.

I ordered 1 cover gasket 11483-18H00 for $8 and 2 upper bolt gaskets 0916806023 for about a buck each or so and a tube of 1207 bond (I used Honda Bond. It's a semi-hardening sealer).

Here's a shot of everything you need to get started. And yes, Red Bull was needed.

Step one - pull off the primary drive cover.

Step two - pull off the body work, if in fact you have some.

Step three - take out the 10 generator 8mm bolts.

Step four - notice, the top two bolts have a gasket washer on them.

Step five - pull the cover off straight and in-line. It is tough to pull as there is a big magnet holding things in place in the generator. There are two dowel pins lining it up too. Just pull slowly with both hands and watch getting pinched as it slams back shut!!!

A bit of oil comes out too - just be prepared.

A bit of oil comes out too - just be prepared.Step six - look inside for any damage. In mine, there was none.

Step seven - scrape off ALL old gasket materials.

Step eight - use your 1207 sealer (Honda Bond or Suzuki Bond) and lightly hit the left and right sides with a little where the case halves come together.

Step nine - ensure both dowel pins are in, then install your new gasket.

Step ten - SLOWLY with both hands and STRAIGHT IN, reinstall the cover onto the dowel pins. WATCH PINCHING YOUR FINGERS!! Use a rubber tap hammer to SLOWLY tap it back in place. When ready and it is aligned, insert the top two bolts. I used new gasket washers only because they were cheap and I like new stuff. Reinstall the balance of the bolts and tighten. The manual did not seem to give a torque setting, so I just tightened.

Step eleven - reinstall the primary drive cover, wipe everything off, and fire it up to do a leak check. In my case, all was fine!!

Step twelve - reinstall the body work if in fact you have some, polish it up again, and be thankful it all works again!!! After this twelfth step, consider you and your bike healed.

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to