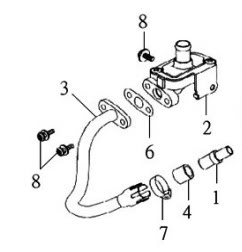

Hi. What is a good way to cap a short 1/2" metal tube that is sticking out of the cylinder head. This tube (#1) is for the AIC system on a chinese scooter.

I'm permanently removing the long tube with fingers on one end (#3) and the dookhicky (#2). So I need to cap the end of the tube (#1).

The open end of tube (#1) in photo below is press fitted into the cylinder; so removal of this tube may be nearly impossible.

A copper bushing (#4) keeps the connection air tight.

Some people on scooter forum buy a copper cap from Home Depot, and then cut fingers on it like the original long tube (#3). They put the cap over the bushing and just clamp it down with the hose clamp (#7). But that looks dodgy to me because I generally don't trust hose clamp. And losing the bushing (#4) would be a bad idea, since this is a chinese scooter, replacement parts are not available.

Can I weld this 1/2" tube closed? Will the heat damage the cylinder head or the engine?

To mechanic geniuses in here. Any idea?

I'm permanently removing the long tube with fingers on one end (#3) and the dookhicky (#2). So I need to cap the end of the tube (#1).

The open end of tube (#1) in photo below is press fitted into the cylinder; so removal of this tube may be nearly impossible.

A copper bushing (#4) keeps the connection air tight.

Some people on scooter forum buy a copper cap from Home Depot, and then cut fingers on it like the original long tube (#3). They put the cap over the bushing and just clamp it down with the hose clamp (#7). But that looks dodgy to me because I generally don't trust hose clamp. And losing the bushing (#4) would be a bad idea, since this is a chinese scooter, replacement parts are not available.

Can I weld this 1/2" tube closed? Will the heat damage the cylinder head or the engine?

To mechanic geniuses in here. Any idea?

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to