OldTLSDoug

Forum Supporter

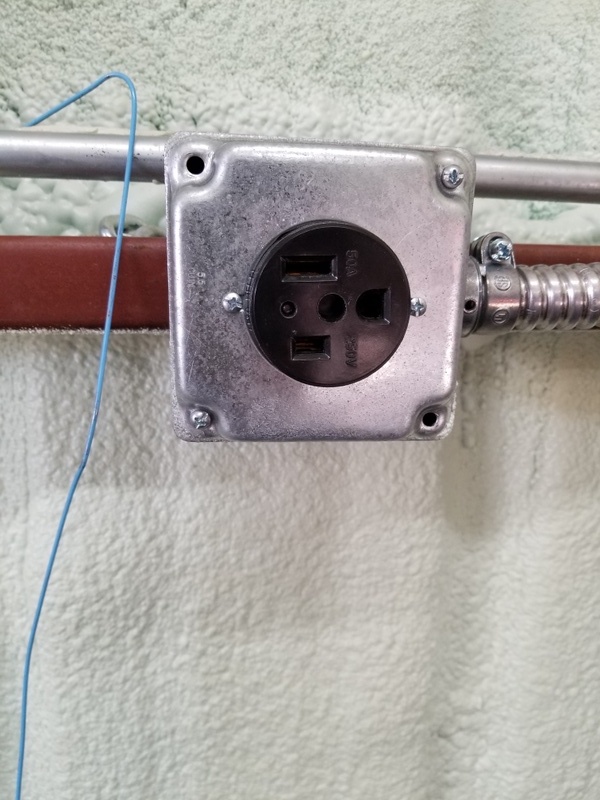

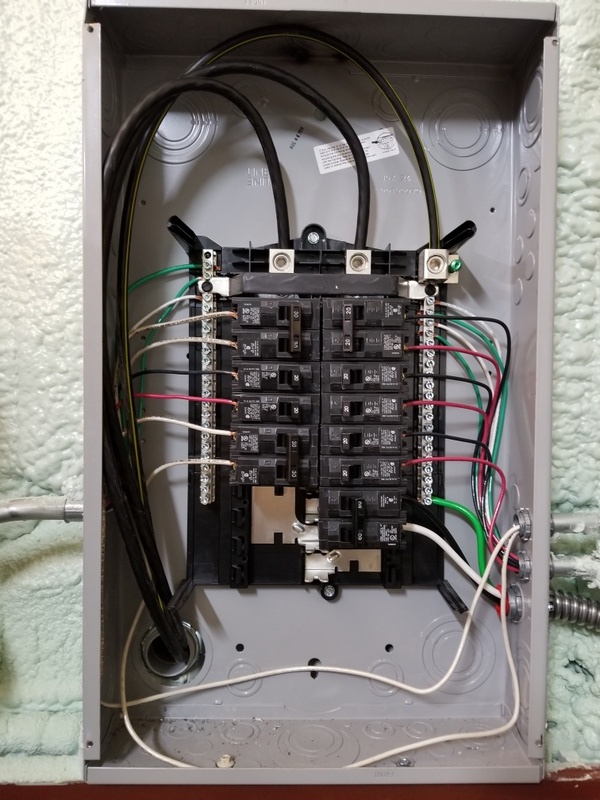

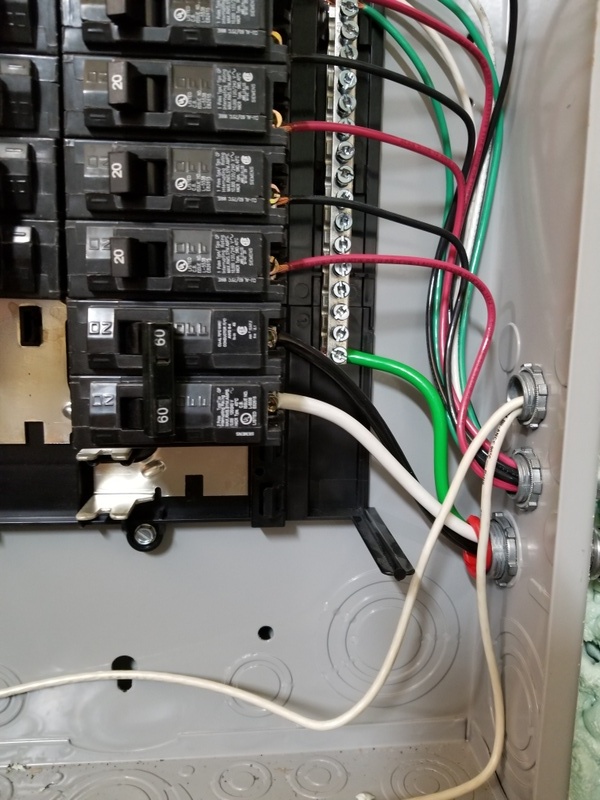

I had my buddy Jim over today, and we ran some 6 gauge wire to a new outlet in preparation for my new (hopefully soon) tig welder to play with. When I built the shop I told them I wanted two 240 outlets for welding. So they gave me two 10 gauge wires to 30 amp breakers. So that wouldn't do, the welders I am looking at need a 50 amp breaker, so I put in the 60 amp circuit. Didn't break anything, but the 25 ft of wire cost $100.00. Whew!!

Can you pick out what we installed?

Can you pick out what we installed?

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to