We modify our bikes, its what we do.

Sometimes we remove a safety switch, a light, or another part that leaves you with an unused and now open unsealed wire end or plug.

Or we swap an OEM part that used 3 wires to power and control it, but the after market one only uses 2.

What ever the reason, we sometimes end up with what is now an extraneous wire, bullet connector or terminal.

Those left over wires or terminals can cause a short to ground if not covered, they can lead to corrosion as it starts at open and unprotected terminal crimped to the wire and worms its way into the wiring harness.

Snipping that unused left over wire and covering with a wrap of electrical tape is a time honored method and it works, until it doesn't. The tape comes loose after a summer of riding, water gets in when you play in the mud, cross a creek, wash the bike and starts corrosion or worse, the hot wire end grounds out and you have a blown fuse or damaged electrical component.

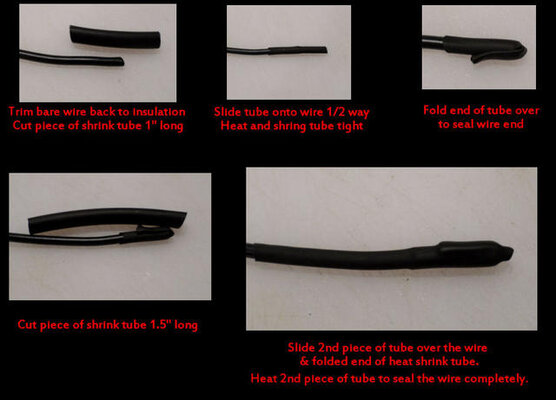

Here is a better way to seal off that unused wire end.

It takes two pieces of heat shrink tubing (or three if binding together more then one sealed wire)

I prefer to use double wall adhesive lined heat shrink tubing for the job.. I use 3M Adhesive-Lined Polyolefin Heat Shrink Tubing and 3M non lined Polyolefin Heat Shrink Tubing, but many other brands are out there as well. Do a Google search for "heat shrink tubing" and "adhesive lined heat shrink tubing" then pick what you want in the size and color.Look at the shrink ratios and starting size to understand what size it will end up.

Regular heat shrink tube does a ok job as well for sealing an unused wire end, just not quite as weatherproof...Suggest you always use the dielectric silicon on wire tip in step one is not using adhesive lined tubing.

Consider buying just a little more then needed for the job at hand and soon enough you'll have a collection that gives you the proper size tubing most every time.

If you are planning on that sealed wire being often submerged in water or mud, you can coat the very end of the wire wire in the first step with dielectric silicone to further help water proof the open end of the wire.

If you have more then one wire left over, you can slip a third piece of tubing over the wires and shrink down to create a niece secure, protected bundle that loose clean. Like this

For this particular task I was asked to keep the associated plug in place and terminate the unused wires after the plug. This gives the owner several options... If desired later at time of resale, or change of mind, a simple job of re-soldering the cut off switch and its wires returns the wiring harness and bike to "stock".

Also in this case that plug and its circuit is a key on hot 12v power and ground source the owner can use to power (though a fuse please) a low wattage add on device, like USB charge port, GPS, ect. and it has a nice modern sealed plug to disconnect that added mod as needed.

Sometimes we remove a safety switch, a light, or another part that leaves you with an unused and now open unsealed wire end or plug.

Or we swap an OEM part that used 3 wires to power and control it, but the after market one only uses 2.

What ever the reason, we sometimes end up with what is now an extraneous wire, bullet connector or terminal.

Those left over wires or terminals can cause a short to ground if not covered, they can lead to corrosion as it starts at open and unprotected terminal crimped to the wire and worms its way into the wiring harness.

Snipping that unused left over wire and covering with a wrap of electrical tape is a time honored method and it works, until it doesn't. The tape comes loose after a summer of riding, water gets in when you play in the mud, cross a creek, wash the bike and starts corrosion or worse, the hot wire end grounds out and you have a blown fuse or damaged electrical component.

Here is a better way to seal off that unused wire end.

It takes two pieces of heat shrink tubing (or three if binding together more then one sealed wire)

I prefer to use double wall adhesive lined heat shrink tubing for the job.. I use 3M Adhesive-Lined Polyolefin Heat Shrink Tubing and 3M non lined Polyolefin Heat Shrink Tubing, but many other brands are out there as well. Do a Google search for "heat shrink tubing" and "adhesive lined heat shrink tubing" then pick what you want in the size and color.Look at the shrink ratios and starting size to understand what size it will end up.

Regular heat shrink tube does a ok job as well for sealing an unused wire end, just not quite as weatherproof...Suggest you always use the dielectric silicon on wire tip in step one is not using adhesive lined tubing.

Consider buying just a little more then needed for the job at hand and soon enough you'll have a collection that gives you the proper size tubing most every time.

If you are planning on that sealed wire being often submerged in water or mud, you can coat the very end of the wire wire in the first step with dielectric silicone to further help water proof the open end of the wire.

If you have more then one wire left over, you can slip a third piece of tubing over the wires and shrink down to create a niece secure, protected bundle that loose clean. Like this

For this particular task I was asked to keep the associated plug in place and terminate the unused wires after the plug. This gives the owner several options... If desired later at time of resale, or change of mind, a simple job of re-soldering the cut off switch and its wires returns the wiring harness and bike to "stock".

Also in this case that plug and its circuit is a key on hot 12v power and ground source the owner can use to power (though a fuse please) a low wattage add on device, like USB charge port, GPS, ect. and it has a nice modern sealed plug to disconnect that added mod as needed.

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to