Ready, set............ BUILDb78: Parts are headed your way...

rt

-

Welcome to the Two Wheeled Texans community!

Welcome to the Two Wheeled Texans community!  Feel free to hang out and lurk as long as you like. However, we would like to encourage you to register so that you can join the community and use the numerous features on the site. After registering, don't forget to post up an introduction!

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to register so that you can join the community and use the numerous features on the site. After registering, don't forget to post up an introduction!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XR 600 Tracker project

- Thread starter road_thing

- Start date

Tear down done, check your PM's we can go from there.

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Got your PM's and responded. Make it so!

rt

rt

Been an adventure to put a parts order together....3 venders plus a supplier for the shock and fork spacer materiel. Kind of like an Easter egg hunt.

Kind of like an Easter egg hunt.

Road_Thing, shoot me an email so i can send something back to you.

Road_Thing, shoot me an email so i can send something back to you.

Last edited:

Soooo, Ahhhh, come on over.... we is ready to play.

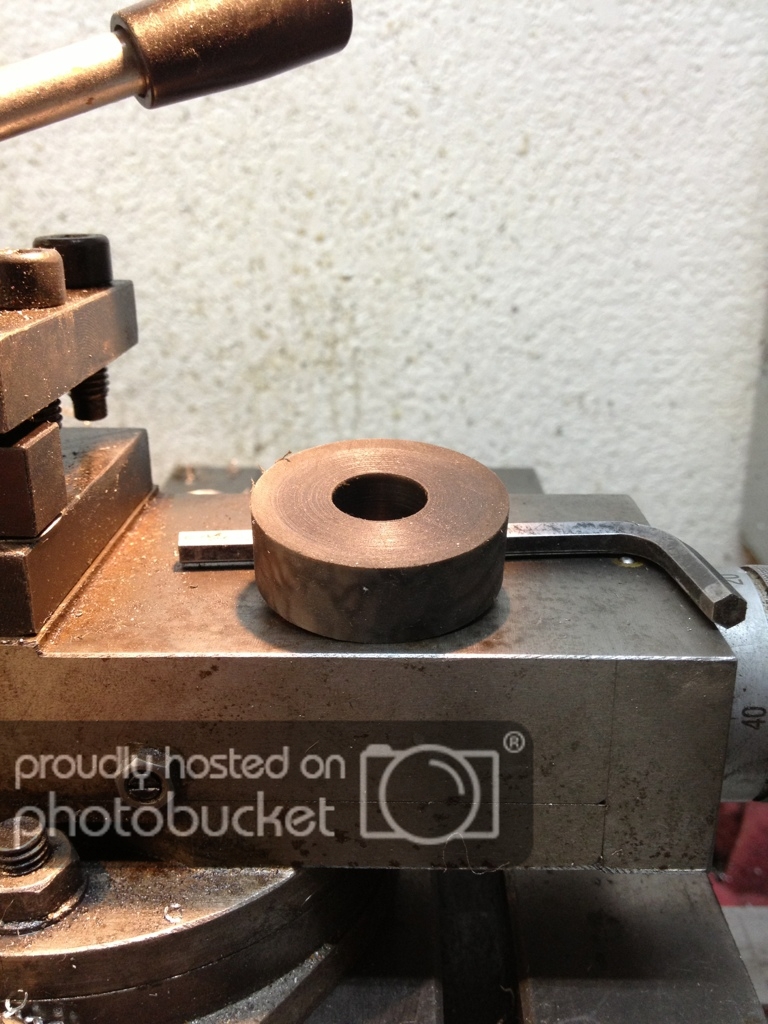

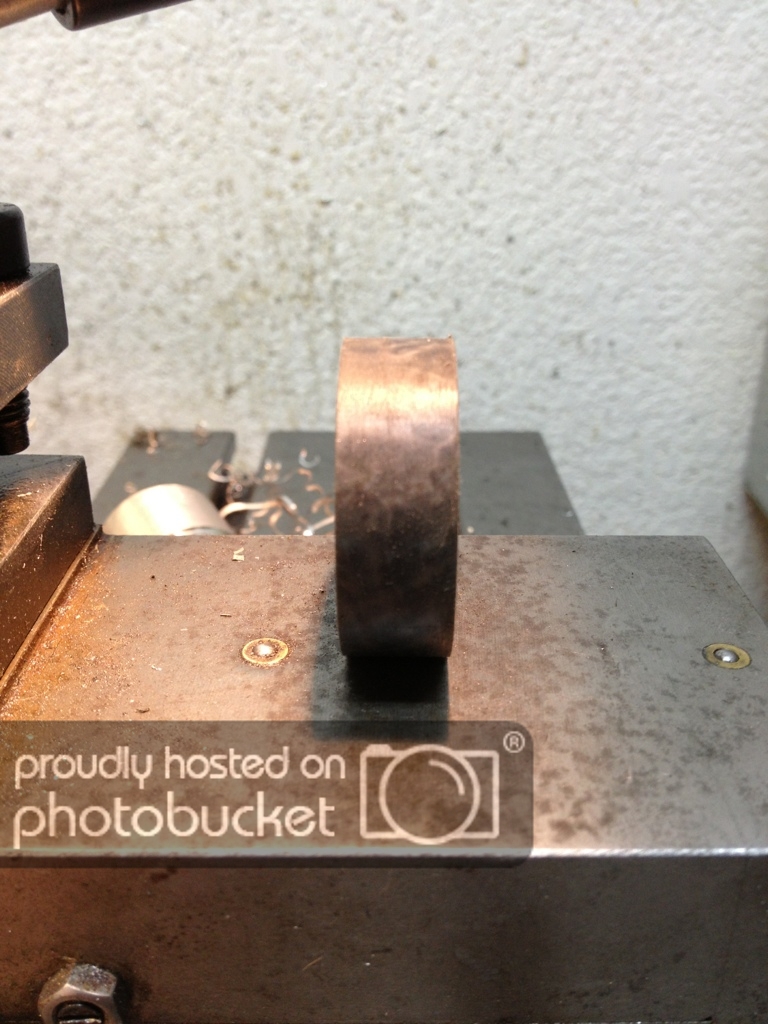

Two fork lowering spacers 2.000" long

TEST FIT

Purrrrrrfect

And a shock spacer made from NYLATRON GSM Nylon

We are all set to put these things together tomorrow.

See ya late morning.

Two fork lowering spacers 2.000" long

TEST FIT

Purrrrrrfect

And a shock spacer made from NYLATRON GSM Nylon

We are all set to put these things together tomorrow.

See ya late morning.

Last edited:

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Have brake cleaner, will travel...

I'm gonna try to get out of here by 0700, should put me at your place 0930-1000. I'll call if ETA changes.

Thanks!

rt

I'm gonna try to get out of here by 0700, should put me at your place 0930-1000. I'll call if ETA changes.

Thanks!

rt

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Thanks Erik! I'm gonna hurry up and get this thing back on two wheels now that the suspension is done. Hope all the oil came up off the floor OK...

rt

rt

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Here's where it sits this afternoon--motor's back in the frame, and the shock, forks and wheels are in place. I think I've got everything that I need to finish it on hand, now.

What could possibly go wrong?

rt

Thisblooks like an awesome project!!! Ever thought of.maybe some CBR forks, with custon machined spacers for the wheels? Itd lower the front quite a bit

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Billy: Thanks! The front and rear are lowered by 2", thanks to Bronco78. I'm gonna put it together and run it as-is for a while. I hit a little snag yesterday--twisted off an exhaust stud in the head.  I'm gonna try to weld a nut on it and back it out later today, but I've got set of left-hand drill bits coming Tuesday, just in case.

I'm gonna try to weld a nut on it and back it out later today, but I've got set of left-hand drill bits coming Tuesday, just in case.

The rest of it is together now, just need to finish the paint, out oil in it and fire it up.

rt

The rest of it is together now, just need to finish the paint, out oil in it and fire it up.

rt

Whoa! I missed the ENTIRE second page of this. Im really excited about this build! Ive wanted to build a dirtbike platform street/dirt tracker for awhile. I really like the red frame and totally agree on the white body parts scheme.

What kind of did you use? Ive always had really good luck with duplicolor stuff, and spraymax 2k aerosol clear coat. NOTHING can distort that clear!

What kind of did you use? Ive always had really good luck with duplicolor stuff, and spraymax 2k aerosol clear coat. NOTHING can distort that clear!

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Generic automotive base/clear. I've got the tank & seat painted white and clearcoated, need to wetsand and shoot more clear. Thinking about a "rising sun" motif on the tank.

rt

rt

Is it a 2 part clear (have to mix the hardner in)? Or is it the autozone "automotive" clear lacquer/enamel? Reason i ask, if its not a chemically hardned (2 part) clear (out of a HVLP gun) it will nit be impervious to fuel. They all claim to be, but absolutely are not.

Heres a tank i did. I used the "yellow chrome" duplicolor paint shop premixed enamel from autozone. Its a perfect match to the famous yamaha competition yellow. After it dried i wet sanded with 1500. I applied the decals, and used the spraymax 2 part aerosol clear. It IS a 2 part clear, AND its an aerosol product. The hardner is in a seperate chamber, and you have to activate it before use. Pretty cool stuff. AND its the ONLY aerosol product i know of that ACTUALLY IS chemical proof. The catch is- youve gotta let the base coat enamel dry for about 5 days. This is the tank prior to wetsand, and final polish

Heres a tank i did. I used the "yellow chrome" duplicolor paint shop premixed enamel from autozone. Its a perfect match to the famous yamaha competition yellow. After it dried i wet sanded with 1500. I applied the decals, and used the spraymax 2 part aerosol clear. It IS a 2 part clear, AND its an aerosol product. The hardner is in a seperate chamber, and you have to activate it before use. Pretty cool stuff. AND its the ONLY aerosol product i know of that ACTUALLY IS chemical proof. The catch is- youve gotta let the base coat enamel dry for about 5 days. This is the tank prior to wetsand, and final polish

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Wow, that looks great! I'm using 2 part clear.

Rt

Rt

Good deal! Pics?

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Here's where it sits as of this morning:

And this is my "little snag":

I tried welding a nut on the end and backing it out with a socket, but it didn't work. I should have a set of left-handed drill bits this afternoon. If that doesn't get it out, I'll be pulling the head...

rt

And this is my "little snag":

I tried welding a nut on the end and backing it out with a socket, but it didn't work. I should have a set of left-handed drill bits this afternoon. If that doesn't get it out, I'll be pulling the head...

rt

I tried welding a nut on the end and backing it out with a socket, but it didn't work. I should have a set of left-handed drill bits this afternoon. If that doesn't get it out, I'll be pulling the head...

rt

Why not try welding a flat washer to the stud 1st, then the nut to the washer ,

then add some heat around the around the area and start back and forth slowly , you can get it .

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Marko, the problem I had with welding to the stud is that the nuts melt before the stud, I can't get them to fuse. I think the head pulls so much heat out of the stud that I can't get it to puddle. It's a pretty small stud. No threads left, now.

rt

rt

- Joined

- Jan 16, 2008

- Messages

- 825

- Reaction score

- 0

- Location

- Dayton,Texas

- First Name

- Bryan

- Last Name

- Williams

Very cool looking bike. You thought about trying an Easy Out on the broken exhaust bolt

- Joined

- May 18, 2006

- Messages

- 1,953

- Reaction score

- 1,959

- Location

- Leander

- First Name

- Paul

- Last Name

- Zuniga

Marko, the problem I had with welding to the stud is that the nuts melt before the stud, I can't get them to fuse. I think the head pulls so much heat out of the stud that I can't get it to puddle. It's a pretty small stud.

Thin gauge wire welder.

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

Well, the left hand bits didn't work. I got the stud drilled all the way out to 1/4 "(it's a M8x1.25 stud) but it wouldn't break loose. What I've got now is a 0.25" hole in the aluminum head, lined with remnants of the threads that were on the stud. I'm trying to decide whether to pull the head and take it to a machine shop for repair, or drill the hole out and put a threaded plug in it.

rt

rt

Helicoil ?

Marko, the problem I had with welding to the stud is that the nuts melt before the stud, I can't get them to fuse. I think the head pulls so much heat out of the stud that I can't get it to puddle. It's a pretty small stud. No threads left, now.

rt

Thin gauge wire welder.

The 4 or 5 times I did it was with a tig torch with foot control .

The were 6mm threads on atc 70's , they were notorious for exhaust studs breaks and plug threads stripped .

- Joined

- Apr 10, 2009

- Messages

- 496

- Reaction score

- 1

- Location

- Welcome, TX

- First Name

- tom

- Last Name

- mccarroll

I'm going to try a helicoil. Looks like a good candidate.

rt

rt

I'm going to try a helicoil. Looks like a good candidate.

rt

Yup, don't waste any more time of effort, drill out and install a Thread repair coil or TimeSert. It is not a critical fastener, nor requires a perfectly aligned stud, or surface.. It is just is a clamp point for the header flange.