Due to time constraints, and work getting in the way, I haven't made much progress on the HFT trailer project. It's been sitting in front of my garage with half the decking on it since Saturday, and it's going to keep sitting and getting rained on until at least this Saturday, if I can get a break in the rain to work on it.

Here are some quick notes and pictures.

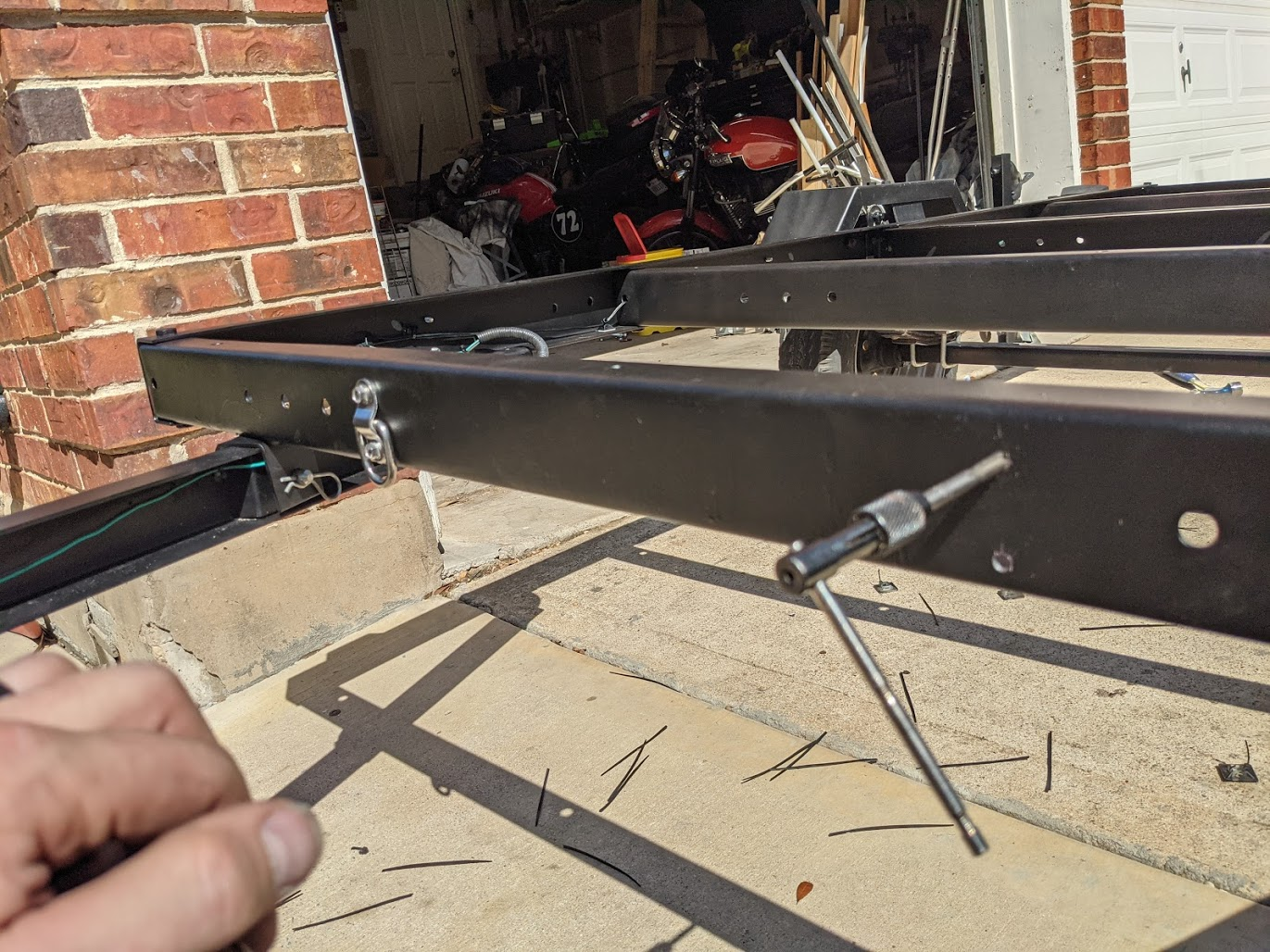

Paint on it, getting ready to start mounting all of the D rings and new decking.

That paint really doesn't stick as well as I had hoped. It's pretty easy to chip off. But so what. It's a $300 utility trailer.

I broke the first several 1/4" screws I attempted to use and had to drill them out when putting on the D rings, and decided to just tap all of the holes manually rather than eating up more screws. This sort of worked.

I made a template to drill the holes for the decking. Then the plan was to use these #10 thread cutting screws to mount them.

The stainless hardware I ordered is awful. About one in three screws loses its threads, strips the head, or snaps off. Here's an idea of how bad this is, and this is not even the entire pile of broken screws from mounting half of the decking:

I don't have a #10-24 tap, so I am stuck trying to make these crummy screws work. Glad I bought extra. Probably worth it to pick up a tap and pre-tap the rest of the holes.

I have half of the decking installed, and learned a lot about how not to do it on that half, so hopefully the 2nd half will go better/easier.

I am still working out how to do the sides, but that's not a critical piece for me to finish. Critical is the decking so I can fold it up and put it away. I also may need new lights, since the lens on one is broken.

Here are some quick notes and pictures.

Paint on it, getting ready to start mounting all of the D rings and new decking.

That paint really doesn't stick as well as I had hoped. It's pretty easy to chip off. But so what. It's a $300 utility trailer.

I broke the first several 1/4" screws I attempted to use and had to drill them out when putting on the D rings, and decided to just tap all of the holes manually rather than eating up more screws. This sort of worked.

I made a template to drill the holes for the decking. Then the plan was to use these #10 thread cutting screws to mount them.

The stainless hardware I ordered is awful. About one in three screws loses its threads, strips the head, or snaps off. Here's an idea of how bad this is, and this is not even the entire pile of broken screws from mounting half of the decking:

I don't have a #10-24 tap, so I am stuck trying to make these crummy screws work. Glad I bought extra. Probably worth it to pick up a tap and pre-tap the rest of the holes.

I have half of the decking installed, and learned a lot about how not to do it on that half, so hopefully the 2nd half will go better/easier.

I am still working out how to do the sides, but that's not a critical piece for me to finish. Critical is the decking so I can fold it up and put it away. I also may need new lights, since the lens on one is broken.

Last edited:

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to