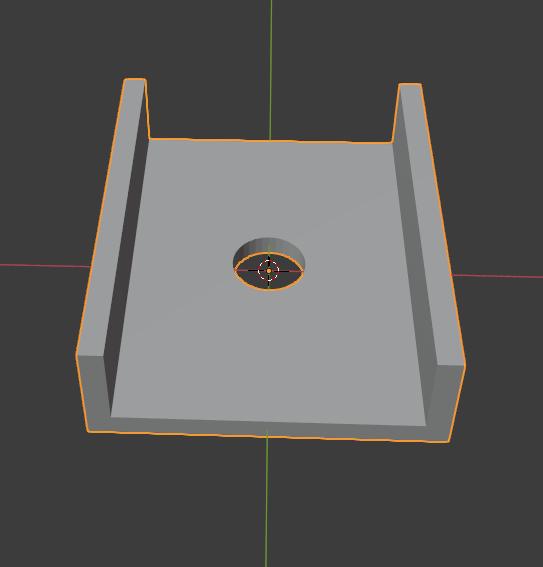

I need 2 small brackets made. the big cnc shops around here ...well its not worth their time and I can't blamethem..... I'd rather not give me money to alibaba either....

any idea where I can get this made ?

any idea where I can get this made ?

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to