We have a great little radiator shop in Waxahachie that does a huge business making and repairing hydraulic, brake and ac hoses. They made the extended brake lines for my tenere for me. If you have a shop like that in your area it would be worth a visit. To get their ideas and see what options are available.

-

Welcome to the Two Wheeled Texans community!

Welcome to the Two Wheeled Texans community!  Feel free to hang out and lurk as long as you like. However, we would like to encourage you to register so that you can join the community and use the numerous features on the site. After registering, don't forget to post up an introduction!

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to register so that you can join the community and use the numerous features on the site. After registering, don't forget to post up an introduction!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making heated gear

- Thread starter longhorn2000

- Start date

- Joined

- Apr 9, 2018

- Messages

- 1,067

- Reaction score

- 1,139

- Location

- Friendswood

- First Name

- Randy

- Last Name

- Jacobs

You realize that on AliExpress, for about 20 bucks you can get a pretty decent heated vest that works off a phone charging brick. They work very well. On low heat, a brick will last all day. Just be careful of sizes. A large is most people's small. They are best worn over an undershirt with something over them. You won't run them on medium or high for very long, as they get pretty hot.

- Joined

- Sep 4, 2017

- Messages

- 2,947

- Reaction score

- 3,067

- Location

- Katy, Republic of Texas

- First Name

- Nolan

You are making a solution more complicated and dangerous than the current solution.

You want to run boiling fluid across your body it tiny tubes under pressure? Really?

Sorry, I will be the one to say this is just a stupid idea.

You want to run boiling fluid across your body it tiny tubes under pressure? Really?

Sorry, I will be the one to say this is just a stupid idea.

I agree with you but i also see his desire to try something new. Something he made.You are making a solution more complicated and dangerous than the current solution.

You want to run boiling fluid across your body it tiny tubes under pressure? Really?

Sorry, I will be the one to say this is just a stupid idea.

My three main concerns with this project are

1) hot antifreeze under pressure near his body.

2) by the time the hoses are strong enough to be burst proof they will tether him to the bike when it goes down.

3) having hoses in his clothing is just going to be miserable. Making them stiff and lumpy.

- Joined

- Apr 9, 2018

- Messages

- 1,067

- Reaction score

- 1,139

- Location

- Friendswood

- First Name

- Randy

- Last Name

- Jacobs

I agree, plus the potential to doing damage to is bike is greatly increased. What happens is a fitting or hose goes bad? If he is not burnt, the motor will.

- Joined

- Sep 4, 2017

- Messages

- 2,947

- Reaction score

- 3,067

- Location

- Katy, Republic of Texas

- First Name

- Nolan

I agree it is OK to think out of the box, some pretty amazing things get invented that way, but this is just plain dangerous.I agree with you but i also see his desire to try something new. Something he made.

My three main concerns with this project are

1) hot antifreeze under pressure near his body.

2) by the time the hoses are strong enough to be burst proof they will tether him to the bike when it goes down.

3) having hoses in his clothing is just going to be miserable. Making them stiff and lumpy.

I did not even think about the part that he may be tethered to the bike, and if in an accident and the hoses rip, there is hot coolant spewing even more directly on him than if the radiator/coolant hoses were damaged.

And to clarify, I am not calling him stupid, just the idea of doing it.

We all sometimes come up with ideas that sound great in our heads, but when we put them down on paper or tell others, we realize we did not think it out.

I know we all have had those moments, and hopefully we did not have any bad results from them, but some of us have.

Years ago at a bike show I bought a kit to make my own heated jacket. 78 feet of 28 gauge wire with an off and on switch. It worked great except when the wires touched together it would short out and I would have a hard time finding the short.

- Joined

- Nov 7, 2004

- Messages

- 17,405

- Reaction score

- 5,545

- Location

- Sun Lakes & Show Low, Arizona

- First Name

- Brian

Great Ideas All Start As Dumb Ideas

It’s no surprise that most of the successful Startups today started off as a completely bad idea. As it turns out, given the right circumstances, the dumbest idea can become the most profitable company.

Years ago at a bike show I bought a kit to make my own heated jacket. 78 feet of 28 gauge wire with an off and on switch. It worked great except when the wires touched together it would short out and I would have a hard time finding the short.

This may tick off some of the right boxes -- there are plenty of instructions and materials sources for DIY heated gear, typically using carbon tape.

Then again, the ingenuity here should be saluted - hopefully not across a bed in the burn unit.

Just: why?

Seriously, this is actually one of the great uses for electricity. And your motorcycle is dumping excess electrical current into a heat sink already, why not let it sink that heat into your jacket and gloves? Plus, there's no risk of a crack in a hose or error in unplugging/replugging that your motorcycle will overheat.

And that's not to mention the risk if the jacket leaks hot coolant. Not just that it'll burn you, but when that happens while you are riding, you're likely to crash and potentially hurt other people in the process. Because believe me, a sudden addition of 190 degree liquid coolant onto your skin will get an immediate involuntary reaction from your body that is not really compatible with safe motorcycle operation.

Seriously, this is actually one of the great uses for electricity. And your motorcycle is dumping excess electrical current into a heat sink already, why not let it sink that heat into your jacket and gloves? Plus, there's no risk of a crack in a hose or error in unplugging/replugging that your motorcycle will overheat.

And that's not to mention the risk if the jacket leaks hot coolant. Not just that it'll burn you, but when that happens while you are riding, you're likely to crash and potentially hurt other people in the process. Because believe me, a sudden addition of 190 degree liquid coolant onto your skin will get an immediate involuntary reaction from your body that is not really compatible with safe motorcycle operation.

So with everyone’s worry’s about being burned and the like, I have decided I will make a liquid to liquid heat exchanger instead. I have found several that were made with just 1 1/2” pipe with brazed copper tubing looped through it. And a windshield washer pump or something slightly strong would work just fine to circulate the heater fluid.

As for the concerns of being tethered to the bike by hoses, the tethered airbag jackets use rip cords that require a force upwards of 75lbs to set off. The 1/4” hose would long be ripped apart before it reaches that kind of force.

I greatly appreciate everyone input into my endeavor, and that’s one of the thing I love about the motorcycle community is that most riders are like me in that they love helping fellow rider and people in general. And this is one of the best forums to be able to see that concept shine.

As for the concerns of being tethered to the bike by hoses, the tethered airbag jackets use rip cords that require a force upwards of 75lbs to set off. The 1/4” hose would long be ripped apart before it reaches that kind of force.

I greatly appreciate everyone input into my endeavor, and that’s one of the thing I love about the motorcycle community is that most riders are like me in that they love helping fellow rider and people in general. And this is one of the best forums to be able to see that concept shine.

Cool stuff. I wish you were creating an AC jacket to cool off in the summer. I’d pay top dollar for an effective/practical AC jacket.

- Joined

- Nov 7, 2004

- Messages

- 17,405

- Reaction score

- 5,545

- Location

- Sun Lakes & Show Low, Arizona

- First Name

- Brian

Top Dollar is exactly what you'll pay.Cool stuff. I wish you were creating an AC jacket to cool off in the summer. I’d pay top dollar for an effective/practical AC jacket.

Motorsports Complete Kits – COOLSHIRT SYSTEMS

dukey33

0

Therein lies the versatility of a liquid-to-liquid heat exchanger.

Leave enough space in the exhanger to load it with ice or ice water and it becomes a cooling garment.

Leave enough space in the exhanger to load it with ice or ice water and it becomes a cooling garment.

Looks like with the high prices of the cooling gear and the relative cheep options of heated gear maybe there is a financial incentive to come up with a viable and less expensive option. Id sure love a nice cool head in the summer crossing west TX to get to Colorado.

Longhorn 2000,

Yours is an old post and you may be onto something different now. But if you are still experimenting with engine coolant-heated wearable-gear the following is my experience with heated and cooled clothing:

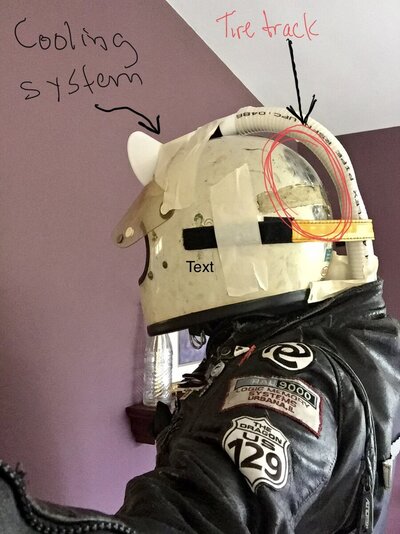

I’ve made heated and cooled gear. For cooling I‘ve used ram-air. A funnel attached to the top of my helmet and bifurcated-tubes run down my back into my jacket. Sucked up bugs and trash. Obviously it didn't work standing still which is when cooling is needed most. I then sewed 32’ of 3/8” tubing into coveralls and fed ice water from a one-gallon cooler using a 12vdc potable water pump. I used plastic QD’s to isolate the water when disconnected. Worked well but the ice didn’t last very long; about 40-minutes on a 90° F day. I then changed the passive cooler for a powered, 12vdc cooler. This extended the the cooling for about 30 additional minutes. I switched to an off the shelf CoolShirt. It comes with plastic QDs. CoolShirt sells entire cooling systems.

The powered coolers are also heaters. Direction of current-flow determines cooling or heating function. This might be an option over using the bikes liquid cooling system for heat. The possibility of a get off causing rider-scalding and or coolant loss is serious. I use electrically heated clothing so I haven’t attempted water-heat.

With my liquid-cooled overalls, should a get off occur I expected the hoses to pull out of the cooler. If you do proceed with engine coolant heat for your suit hydraulic fuses might be a good idea. My only experience with them is in the aviation-field. I have no idea if there are DIY fuses for sale. Might be an interesting challenge to design and make fuses for your application.

Heated seats work remarkably well. I’ve made them out of old heating pads and heating blankets. I see no reason why a cooling-system, heated seat would not be possible. This would eliminate the getting-separated-from-the-bike issue. A simple petcock valve could be used for control.

Working with fluid for heat is messy. Electrical heat is simple compared to liquid-heat. I started making heated visors long before they became commercially available. I was commuting in sub-zero (F) conditions. My heated jacket, gloves, pants and socks made this possible but FogCity and Pinlock visors couldn’t overcome ice buildup. I tried snorkels made of flexible straws but they froze up after a few miles. I first thought I would heat them but then decided that if I were going to route 12vdc to my helmet for this heating purpose, why not just heat the visor.

I did this with heating pad wires scotch-taped to my helmet’s visor. Worked a treat. Now snowmobile helmets come with conductive poly-visors; no wires to obstruct the view. Many replacement heated visors can be modified to fit standard visors.

More than enough heating wire is available in a queen sized heated blanket. The wire can be hand-tacked into shirt, pants and socks (sewing the wire into gloves is tedious but can be done).

Once hand-tacked onto a garment, machine zigzagging will better secure the wire element. This is not necessary if one is patient enough to hand sew the wires.

I’ve learned independent control of each piece of heated-gear is desirable. This adds complications but it’s worth it. Many dual, remote controllers are available. Their application requires a battery powered potentiometer-like controller. The control-batteries don’t last long, maybe two to three hours. They can be wired into the bike’s 12-vdc system with voltage reducers.

General aviation aircraft use heat muff heat exchangers wrapped around the exhaust system, not too different from VW’s air cooled engine cabin heat-system. Some tubing and a 12vdc fan to force the air into the clothing would be required.

Water/glycol-filled flexible copper tubing could be wrapped around the header and exhaust pipes. Flexible tubing could be attached to the copper tubing and then routed into the suit. Convection would supple the motive force required to circulate the heated fluid. A conventional automotive thermostat could be placed in line to guarantee the engine would reach operating temperature. Off the shelf metal QD’s should be able to handle the heat. O rings might need to be replaced to meet elevated thermal needs.

I applaud your pluck. Some of the obstacles which need to be overcome are daunting but as Clarence Darrow said; “Lost causes are the only ones worth fighting for”.

You are in good company. People like us are capable of bringing a turd to a high patina. Sure it’s reinventing wheel; anything in the way of powered clothing you may make has already been done. And it’s been done cheaper; Chinese slaves cannot be beaten for price-point.

But it gives you something to do with your hands…

Steve

Yours is an old post and you may be onto something different now. But if you are still experimenting with engine coolant-heated wearable-gear the following is my experience with heated and cooled clothing:

I’ve made heated and cooled gear. For cooling I‘ve used ram-air. A funnel attached to the top of my helmet and bifurcated-tubes run down my back into my jacket. Sucked up bugs and trash. Obviously it didn't work standing still which is when cooling is needed most. I then sewed 32’ of 3/8” tubing into coveralls and fed ice water from a one-gallon cooler using a 12vdc potable water pump. I used plastic QD’s to isolate the water when disconnected. Worked well but the ice didn’t last very long; about 40-minutes on a 90° F day. I then changed the passive cooler for a powered, 12vdc cooler. This extended the the cooling for about 30 additional minutes. I switched to an off the shelf CoolShirt. It comes with plastic QDs. CoolShirt sells entire cooling systems.

The powered coolers are also heaters. Direction of current-flow determines cooling or heating function. This might be an option over using the bikes liquid cooling system for heat. The possibility of a get off causing rider-scalding and or coolant loss is serious. I use electrically heated clothing so I haven’t attempted water-heat.

With my liquid-cooled overalls, should a get off occur I expected the hoses to pull out of the cooler. If you do proceed with engine coolant heat for your suit hydraulic fuses might be a good idea. My only experience with them is in the aviation-field. I have no idea if there are DIY fuses for sale. Might be an interesting challenge to design and make fuses for your application.

Heated seats work remarkably well. I’ve made them out of old heating pads and heating blankets. I see no reason why a cooling-system, heated seat would not be possible. This would eliminate the getting-separated-from-the-bike issue. A simple petcock valve could be used for control.

Working with fluid for heat is messy. Electrical heat is simple compared to liquid-heat. I started making heated visors long before they became commercially available. I was commuting in sub-zero (F) conditions. My heated jacket, gloves, pants and socks made this possible but FogCity and Pinlock visors couldn’t overcome ice buildup. I tried snorkels made of flexible straws but they froze up after a few miles. I first thought I would heat them but then decided that if I were going to route 12vdc to my helmet for this heating purpose, why not just heat the visor.

I did this with heating pad wires scotch-taped to my helmet’s visor. Worked a treat. Now snowmobile helmets come with conductive poly-visors; no wires to obstruct the view. Many replacement heated visors can be modified to fit standard visors.

More than enough heating wire is available in a queen sized heated blanket. The wire can be hand-tacked into shirt, pants and socks (sewing the wire into gloves is tedious but can be done).

Once hand-tacked onto a garment, machine zigzagging will better secure the wire element. This is not necessary if one is patient enough to hand sew the wires.

I’ve learned independent control of each piece of heated-gear is desirable. This adds complications but it’s worth it. Many dual, remote controllers are available. Their application requires a battery powered potentiometer-like controller. The control-batteries don’t last long, maybe two to three hours. They can be wired into the bike’s 12-vdc system with voltage reducers.

General aviation aircraft use heat muff heat exchangers wrapped around the exhaust system, not too different from VW’s air cooled engine cabin heat-system. Some tubing and a 12vdc fan to force the air into the clothing would be required.

Water/glycol-filled flexible copper tubing could be wrapped around the header and exhaust pipes. Flexible tubing could be attached to the copper tubing and then routed into the suit. Convection would supple the motive force required to circulate the heated fluid. A conventional automotive thermostat could be placed in line to guarantee the engine would reach operating temperature. Off the shelf metal QD’s should be able to handle the heat. O rings might need to be replaced to meet elevated thermal needs.

I applaud your pluck. Some of the obstacles which need to be overcome are daunting but as Clarence Darrow said; “Lost causes are the only ones worth fighting for”.

You are in good company. People like us are capable of bringing a turd to a high patina. Sure it’s reinventing wheel; anything in the way of powered clothing you may make has already been done. And it’s been done cheaper; Chinese slaves cannot be beaten for price-point.

But it gives you something to do with your hands…

Steve