A while ago I bought the dobec TFI from holeshot, along with everything needed for stage1 or 2 build. I did stage 1, and did not proceed with TB butterfly removal because I could not get a single screw to break loose. I busted my p00 bit, I tried heating with a propane torch, they wouldn't budge. So I just used stage 1 settings.

Now I was working on the bike, installing header, flushing coolant, etc. Got bitten by the "while I am at it" bug, and decided to get the secondaries out. I got 2 new heavy duty p00 bits, impact screw driver. Zip. Just stripped the screws. Not a single one would budge.

I said "Screw it, I am drilling them out". So I did. I went through 3 drill bits (2 of them craftsman), and got all of them out... except the #1 unit. I broke 2 bits on that, and on 2nd bit, it got wedged at an angle as it snapped in half.

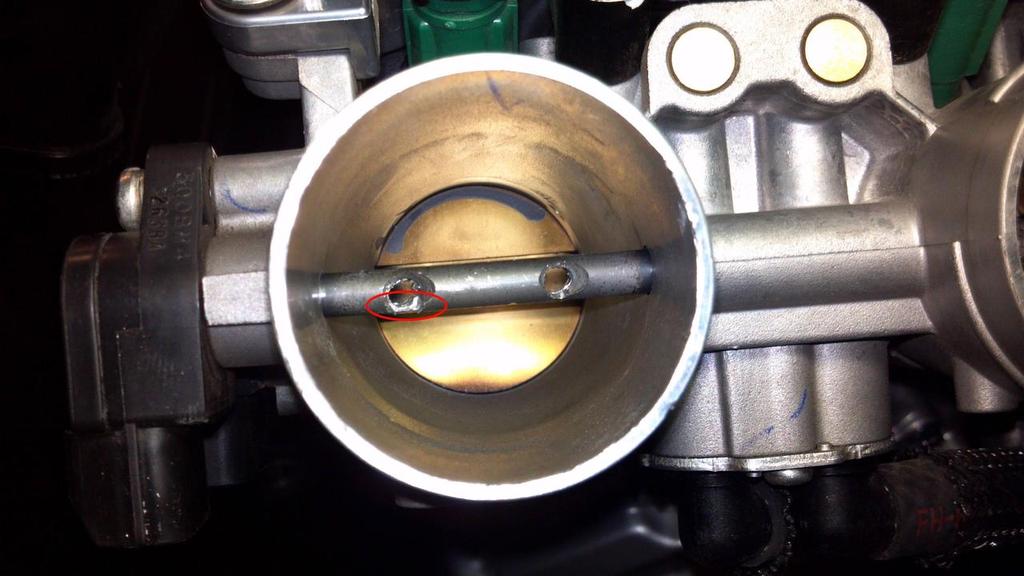

While extracting and cleaning, looks like I tore through the bar. As you can see in the pics:

#1 TB closed position

#1 TB open position

Another TB for comparison, which is how all 3 others turned out (ie. just fine).

So, this being the case, what's the worst that could happen? I am guessing one of the following:

1. Eventually with time, as the motor turns it on/off, it will snap the upper torn beam (as it's closest to the motor) and leave a twisted portion moving?

2. Both halves snap in time since the bottom half will not take twice as much force to twist?

3. Nothing, and it'll be fine since it no longer has to rotate the mass of plates, screws, etc?

What should I do at this point? I remember someone made a post on here about removing the beam and motor, but I am having issues finding that post at this moment

Now I was working on the bike, installing header, flushing coolant, etc. Got bitten by the "while I am at it" bug, and decided to get the secondaries out. I got 2 new heavy duty p00 bits, impact screw driver. Zip. Just stripped the screws. Not a single one would budge.

I said "Screw it, I am drilling them out". So I did. I went through 3 drill bits (2 of them craftsman), and got all of them out... except the #1 unit. I broke 2 bits on that, and on 2nd bit, it got wedged at an angle as it snapped in half.

While extracting and cleaning, looks like I tore through the bar. As you can see in the pics:

#1 TB closed position

#1 TB open position

Another TB for comparison, which is how all 3 others turned out (ie. just fine).

So, this being the case, what's the worst that could happen? I am guessing one of the following:

1. Eventually with time, as the motor turns it on/off, it will snap the upper torn beam (as it's closest to the motor) and leave a twisted portion moving?

2. Both halves snap in time since the bottom half will not take twice as much force to twist?

3. Nothing, and it'll be fine since it no longer has to rotate the mass of plates, screws, etc?

What should I do at this point? I remember someone made a post on here about removing the beam and motor, but I am having issues finding that post at this moment

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to