So, I rode to drill on the first weekend of the month. Battery dead, blah blah blah. Start researching, replace the stator.... NOPE!

Loose magnets.

So. What to do? Well, here's what to do.

First, pout a little bit. Those magnets should be evenly spaced all the way round.

Then, start fixing.

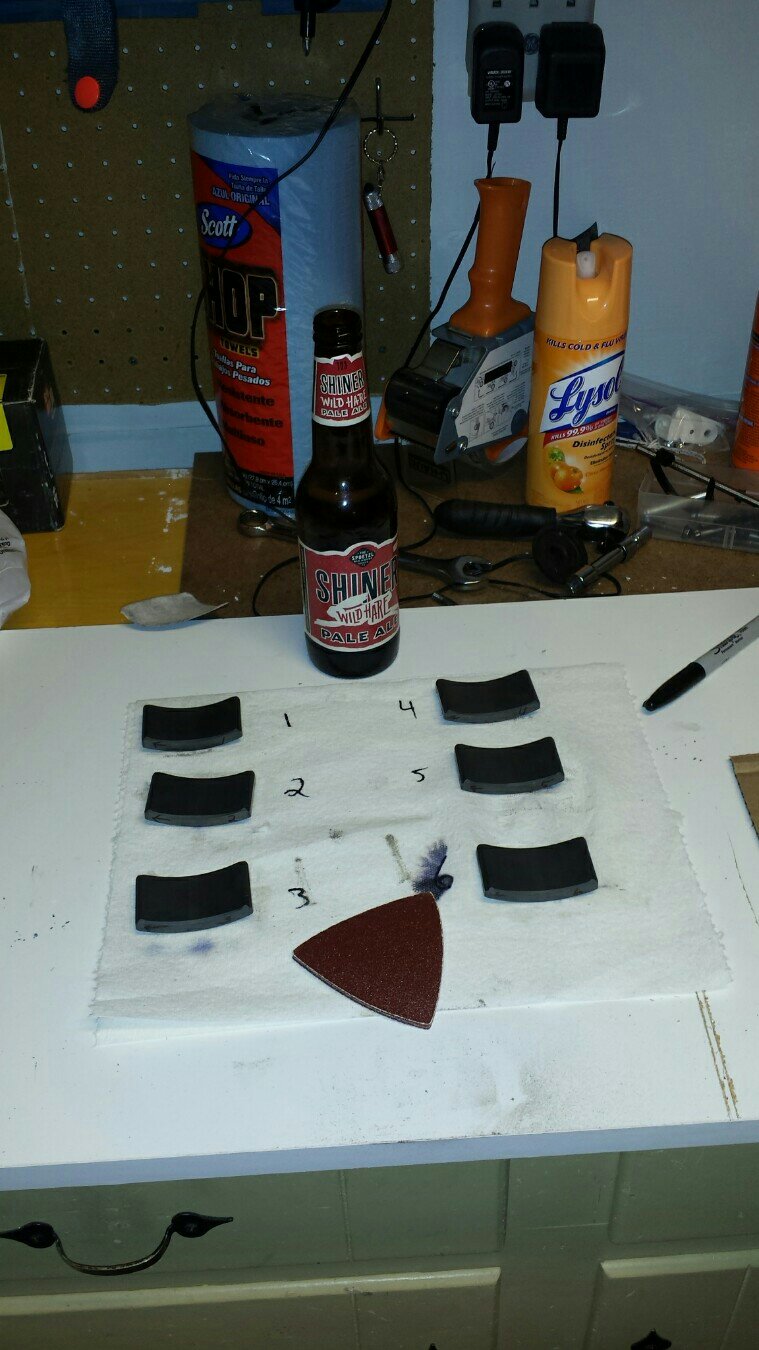

So, all six of mine were loose. The epoxy just wasn't stuck to the flywheel at all. Take them out, labeling them as you go.

The arrow is clockwise, and I numbered them. I don't think it matters what order they go in, but whatever.

Clean off all the oil and junk with the contact cleaner. Do not use brake cleaner. Use electrical contact cleaner. It WILL dissolve sharpie. As you pick each one up to clean it, you need to be sure to replace the marking if it comes off. Keep an eye on what side you marked.

Sand all the epoxy off. I used a Dremel. When you disregard my advice about paying attention to the orientation of the magnets, don't worry. To check which way it goes, put a finger on the other magnets (one at a time) and lower the unknown magnet onto it. They will attract if they are in the right orientation.

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to

Feel free to hang out and lurk as long as you like. However, we would like to encourage you to